Welded Stainless Steel Pipe: Comprehensive Guide

Welcome to Amardeep Steel Centre’s definitive guide on welded stainless steel pipe. Here, we delve into everything you need to know about these essential components in the construction and industrial sectors. From manufacturing processes to size considerations and supplier insights, let’s explore how SS welded pipes are integral to your projects.

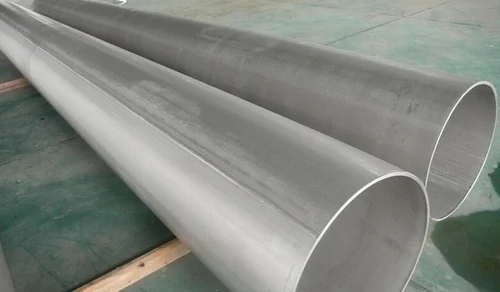

Understanding Welded Stainless Steel Pipes

Welded SS pipes are crafted from strips of stainless steel that are welded together to form a tubular structure. These pipes offer excellent strength, durability, and corrosion resistance, making them ideal for various applications across industries such as oil and gas, chemical processing, automotive, and structural engineering.

Type of SS Welded Pipes

ERW (Electric Resistance Welded) Stainless Steel Pipe

EFW (Electric Fusion Welded) Stainless Steel Pipe

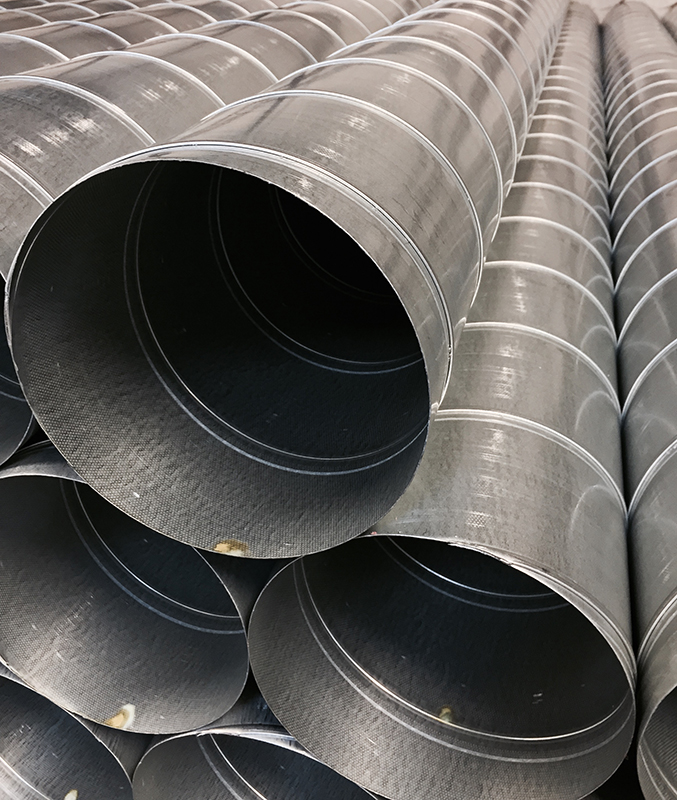

Spiral Weld Stainless Steel Pipe

SAW (Submerged Arc Welded) Stainless Steel Pipe

Schedule Chart for Welded SS Pipes

| Pipe Type | Schedule | Wall Thickness (inches) | Diameter (inches) |

| Stainless Steel ERW Pipes | 5S | 0.065 | 1/8 to 12 |

| 10S | 0.083 | 1/8 to 24 | |

| 40S | 0.109 | 1/8 to 24 | |

| Stainless Steel EFW Pipes | 10 | 0.109 | 2 to 24 |

| 40 | 0.156 | 2 to 24 | |

| 80 | 0.218 | 2 to 24 | |

| Stainless Steel SAW Pipes | STD | 0.237 | 10 to 72 |

| XS | 0.337 | 10 to 72 | |

| XXS | 0.500 | 10 to 72 | |

| Stainless Steel Spiral Welded Pipes | 20 | 0.250 | 6 to 144 |

| 40 | 0.375 | 6 to 144 | |

| 80 | 0.500 | 6 to 144 |

Mechanical Properties Chart for SS Welded Pipes

| Property | ERW Pipes | EFW Pipes | SAW Pipes | Spiral Welded Pipes |

| Tensile Strength (MPa) | High | Very High | High | High |

| Yield Strength (MPa) | Moderate to High | High | High | High |

| Elongation (%) | 20-35 | 25-40 | 20-30 | 20-35 |

| Hardness (HV) | 150-250 HV | 180-280 HV | 160-260 HV | 150-250 HV |

| Impact Strength (J) | Good | Excellent | Good | Good |

Specifications Chart for Stainless Steel Welded Pipes

| Specification | ERW Pipes | EFW Pipes | SAW Pipes | Spiral Welded Pipes |

| ASTM A312 / A358 | Yes | Yes | – | – |

| ASTM A249 / A269 | Yes | – | – | – |

| ASTM A53 / A106 | Yes | – | – | – |

| API 5L / 5LC | – | Yes | Yes | – |

| DIN 2458 / 1626 | Yes | Yes | Yes | Yes |

Chemical Composition Chart for Stainless Steel Welded Pipes

| Element | ERW Pipes | EFW Pipes | SAW Pipes | Spiral Welded Pipes |

| Carbon (C) | ≤ 0.08% | ≤ 0.08% | ≤ 0.08% | ≤ 0.08% |

| Manganese (Mn) | ≤ 2.00% | ≤ 2.00% | ≤ 2.00% | ≤ 2.00% |

| Phosphorus (P) | ≤ 0.045% | ≤ 0.045% | ≤ 0.045% | ≤ 0.045% |

| Sulfur (S) | ≤ 0.030% | ≤ 0.030% | ≤ 0.030% | ≤ 0.030% |

| Silicon (Si) | ≤ 1.00% | ≤ 1.00% | ≤ 1.00% | ≤ 1.00% |

| Chromium (Cr) | 18.0 – 20.0% | 18.0 – 20.0% | 18.0 – 20.0% | 18.0 – 20.0% |

| Nickel (Ni) | 8.0 – 11.0% | 8.0 – 11.0% | 8.0 – 11.0% | 8.0 – 11.0% |

Application Chart for Stainless Steel Welded Pipes

| Application | ERW Pipes | EFW Pipes | SAW Pipes | Spiral Welded Pipes |

| Construction | Structural support | High-pressure systems | Bridges, buildings | Water distribution |

| Oil and Gas | Transmission lines | Pipelines | Offshore platforms | Oil and gas pipelines |

| Chemical Processing | Process piping | Chemical plants | Chemical transfer | Chemical transportation |

| Power Generation | Boiler tubes | Heat exchangers | Power plants | Power distribution |

| Water Treatment | Water supply | Sewage systems | Water treatment plants | Sewage transportation |

Manufacturing Process of Stainless Welded Steel Pipes

The manufacturing process of welded stainless steel pipes involves several key steps:

- Material Preparation: Stainless steel strips or plates are inspected and prepared for forming.

- Forming: The strips or plates are shaped into cylindrical forms either through cold forming or hot forming methods.

- Welding: Longitudinal welding is performed using either Electric Resistance Welding (ERW), Electric Fusion Welding (EFW), Submerged Arc Welding (SAW), or Spiral Welding techniques.

- Sizing and Straightening: The welded pipes undergo sizing to meet dimensional specifications and straightening to ensure alignment.

- Finishing and Testing: Pipes are finished to remove imperfections and undergo various tests to ensure quality, including pressure testing and non-destructive testing (NDT).

Global Reach

Amardeep Steel Centre boasts a robust global presence, committed to delivering unparalleled service and quality to clients around the world. Our dedication to prompt delivery and exceptional customer care sets us apart in the industry. Major corporations across the USA, Europe, Asia, and other regions place their trust in our high-quality stainless steel welded pipes. This widespread trust underscores our reputation for reliability and excellence. By consistently meeting and exceeding the expectations of our international clientele, we continue to solidify our position as a leader in the global steel market.

Countries We Export To

UNITED STATES, EUROPE, UK, UAE, SAUDI ARABIA, OMAN, KUWAIT, JORDAN, QATAR, INDONESIA, MALAYSIA, BRAZIL, SPAIN, ITALY, FRANCE, GERMANY, BAHRAIN, SRI LANKA, AZERBAIJAN, AUSTRALIA, AUSTRIA, PHILIPPINES, TURKEY, RUSSIA, IRAN, IRAQ, CANADA, KOREA, JAPAN, YEMEN, FINLAND, ZIMBABWE, HUNGARY, PORTUGAL, VIETNAM, MOROCCO, THAILAND, SOUTH AFRICA, MEXICO, SINGAPORE, GREECE, KUWAIT, POLAND, NEW ZEALAND, SWEDEN, SWITZERLAND, BELGIUM, BHUTAN, BANGLADESH, TAIWAN, ROMANIA, CAMBODIA, KAZAKHSTAN, AFGHANISTAN.