Amardeep Steel Centre: Your Trusted Source for Inconel Welded Pipes

Welcome to Amardeep Steel Centre, your premier destination for top-quality Inconel welded pipe. As a leading Inconel welded pipes manufacturer and supplier, we take pride in offering a comprehensive range of Inconel welded pipes to meet your industrial needs. Our products are crafted with precision and adhere to the highest industry standards, ensuring exceptional performance and durability.

What are Inconel Welded Pipes?

Inconel welded pipes are high-performance pipes made from Inconel, a family of nickel-chromium-based superalloys known for their exceptional resistance to oxidation and corrosion, even at high temperatures. These pipes are produced by welding, which joins the edges of Inconel sheets or strips to form a seamless and strong bond. Due to their durability and stability in extreme environments, Welded Inconel pipes are widely used in industries such as aerospace, chemical processing, power generation, and oil and gas, where they ensure reliable performance and long-term resilience.

Key Benefits of Using Inconel Welded Pipes

- Superior Corrosion Resistance: Inconel welded pipes offer outstanding resistance to corrosion, making them ideal for use in harsh environments, including chemical processing and marine applications.

- High-Temperature Stability: These pipes maintain their mechanical properties and strength at elevated temperatures, ensuring reliable performance in high-heat applications such as aerospace and power generation.

- Durability and Longevity: Inconel’s robust composition provides exceptional durability, reducing the need for frequent replacements and maintenance, which translates to cost savings over time.

- Versatility: Inconel welded pipes are suitable for a wide range of applications due to their versatility in handling various aggressive environments, including those involving high pressures and corrosive substances.

Types of Inconel Welded Pipes

At Amardeep Steel Centre, we offer a diverse range of Inconel welded pipes to cater to various applications. Our selection includes:

1. Inconel ERW Pipes

Electric Resistance Welded (ERW) Inconel pipes are known for their uniformity and strength. These pipes are manufactured by welding the edges of a rolled strip of metal, creating a strong and seamless joint. Inconel ERW pipes are widely used in applications requiring high-pressure resistance and structural integrity.

2. Inconel EFW Pipes

Electric Fusion Welded (EFW) Inconel pipes are produced by fusing the edges of the metal using an electric arc. This method ensures a robust and homogeneous weld, making EFW pipes suitable for high-temperature and high-pressure environments. Industries such as oil and gas, petrochemical, and marine engineering frequently rely on Inconel EFW pipes for their exceptional performance.

3. Inconel SAW Pipes

Submerged Arc Welded (SAW) Inconel pipes are created by welding under a layer of flux, which protects the weld from contamination. This process results in a high-quality weld with excellent mechanical properties. Inconel SAW pipes are commonly used in structural and mechanical applications where strength and reliability are critical.

4. Inconel Spiral Welded Pipes

Spiral welded pipes are manufactured by continuously welding a strip of Inconel into a spiral shape. This method produces pipes with a consistent wall thickness and excellent flexibility. Inconel spiral welded pipes are ideal for transporting fluids and gases, especially in applications requiring long pipelines with minimal joints.

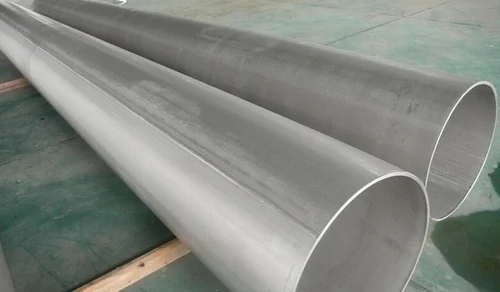

ERW (Electric Resistance Welded) Inconel Pipe

EFW (Electric Fusion Welded) Inconel Pipe

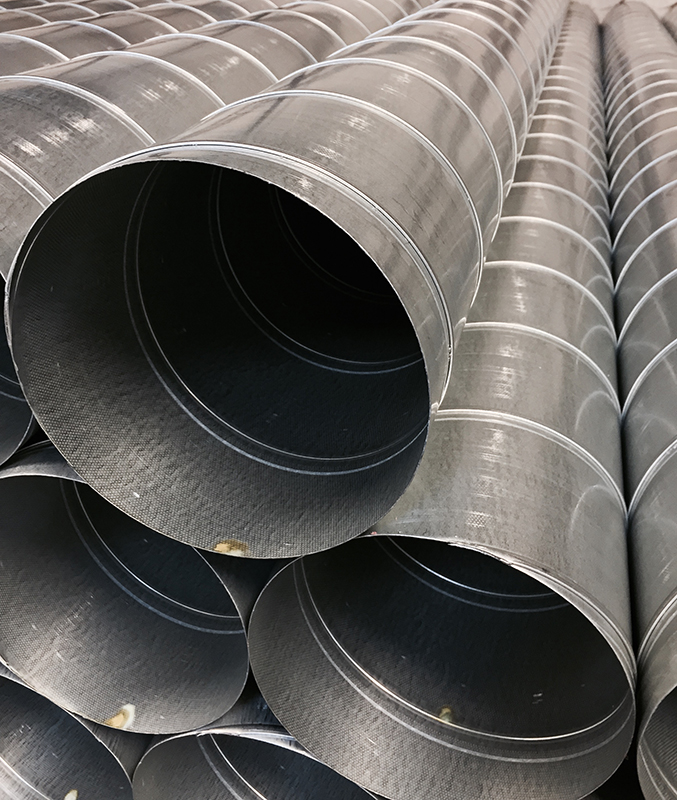

Spiral Welded Inconel Pipe

SAW (Submerged Arc Welded) Inconel Pipe

Advantages of Welded Monel Pipes

- Corrosion Resistance: Monel welded pipes exhibit outstanding resistance to corrosion, making them suitable for marine and chemical processing applications where exposure to corrosive elements is common.

- High Strength: Despite its impressive corrosion resistance, Monel alloys also offer high strength and durability, ensuring reliability in demanding conditions.

- Heat Resistance: Monel alloys maintain their mechanical properties at high temperatures, making them suitable for applications involving elevated temperatures.

- Low Magnetic Permeability: Monel alloys have low magnetic permeability, which is beneficial in applications where magnetic interference needs to be minimized.

Schedule Chart for Inconel Welded Pipes

| Pipe Type | Schedule | Outer Diameter (OD) | Wall Thickness (WT) | Length |

| Inconel ERW Pipes | SCH 5 – XXS | 1/2″ – 24″ | 0.5mm – 20mm | Up to 12 meters |

| Inconel EFW Pipes | SCH 5 – XXS | 1/2″ – 48″ | 1mm – 25mm | Up to 12 meters |

| Inconel SAW Pipes | SCH 5 – XXS | 16″ – 120″ | 5mm – 50mm | Custom lengths |

| Inconel Spiral Welded Pipes | SCH 5 – XXS | 6″ – 120″ | 3mm – 30mm | Custom lengths |

Mechanical Properties Chart

| Property | Inconel ERW Pipes | Inconel EFW Pipes | Inconel SAW Pipes | Inconel Spiral Welded Pipes |

| Tensile Strength | 850 MPa | 850 MPa | 850 MPa | 850 MPa |

| Yield Strength | 400 MPa | 400 MPa | 400 MPa | 400 MPa |

| Elongation | 35% | 35% | 35% | 35% |

| Hardness | 35 HRC | 35 HRC | 35 HRC | 35 HRC |

Chemical Composition Chart

| Element | Inconel ERW Pipes | Inconel EFW Pipes | Inconel SAW Pipes | Inconel Spiral Welded Pipes |

| Nickel (Ni) | 58-63% | 58-63% | 58-63% | 58-63% |

| Chromium (Cr) | 20-23% | 20-23% | 20-23% | 20-23% |

| Iron (Fe) | 5-10% | 5-10% | 5-10% | 5-10% |

| Molybdenum (Mo) | 2.5-3.5% | 2.5-3.5% | 2.5-3.5% | 2.5-3.5% |

| Manganese (Mn) | 0.5% | 0.5% | 0.5% | 0.5% |

| Silicon (Si) | 0.5% | 0.5% | 0.5% | 0.5% |

Specifications Chart

| Specification | Inconel ERW Pipes | Inconel EFW Pipes | Inconel SAW Pipes | Inconel Spiral Welded Pipes |

| ASTM Standard | ASTM B705 | ASTM B705 | ASTM B705 | ASTM B705 |

| ASME Standard | ASME SB705 | ASME SB705 | ASME SB705 | ASME SB705 |

| Size Range | 1/2″ – 24″ | 1/2″ – 48″ | 16″ – 120″ | 6″ – 120″ |

| Wall Thickness Range | 0.5mm – 20mm | 1mm – 25mm | 5mm – 50mm | 3mm – 30mm |

Applications Chart

| Application Area | Inconel ERW Pipes | Inconel EFW Pipes | Inconel SAW Pipes | Inconel Spiral Welded Pipes |

| Aerospace | Engine components, exhaust systems | Engine components, exhaust systems | Engine components, exhaust systems | Engine components, exhaust systems |

| Chemical Processing | Transporting corrosive fluids | Transporting corrosive fluids | Transporting corrosive fluids | Transporting corrosive fluids |

| Power Generation | Steam turbines, heat exchangers | Steam turbines, heat exchangers | Steam turbines, heat exchangers | Steam turbines, heat exchangers |

| Oil and Gas | Transporting hydrocarbons | Transporting hydrocarbons | Transporting hydrocarbons | Transporting hydrocarbons |

| Marine Engineering | Piping systems, structural components | Piping systems, structural components | Piping systems, structural components | Piping systems, structural components |

| Petrochemical | Reactors, process piping | Reactors, process piping | Reactors, process piping | Reactors, process piping |

Why Choose Amardeep Steel Centre for Inconel Welded Pipes?

As a leading Inconel welded pipes supplier, manufacturer, and exporter, Amardeep Steel Centre stands out for several reasons:

1. Unmatched Quality

Quality is at the core of everything we do. Our Inconel welded pipes undergo rigorous testing and inspection to ensure they meet the highest standards of quality and performance. We source our raw materials from trusted suppliers and employ advanced manufacturing techniques to deliver products that exceed customer expectations.

2. Wide Range of Products

We offer a comprehensive range of Inconel welded pipes, including ERW, EFW, SAW, and spiral welded pipes. Our extensive inventory allows us to cater to diverse industrial requirements, ensuring you find the perfect solution for your specific needs.

3. Expertise and Experience

With years of experience in the industry, our team of experts possesses in-depth knowledge of Inconel alloys and their applications. We provide technical support and guidance to help you select the right Inconel welded pipes for your projects, ensuring optimal performance and longevity.

4. Global Reach

As reputable Inconel welded pipes exporters, we have a strong presence in international markets. Our products are trusted by clients worldwide, and we strive to maintain our reputation by delivering excellence in every aspect of our business.

Global Reach

Amardeep Steel Centre boasts a robust global presence, committed to delivering unparalleled service and quality to clients around the world. Our dedication to prompt delivery and exceptional customer care sets us apart in the industry. Major corporations across the USA, Europe, Asia, and other regions place their trust in our high-quality Inconel Welded pipes. This widespread trust underscores our reputation for reliability and excellence. By consistently meeting and exceeding the expectations of our international clientele, we continue to solidify our position as a leader in the global steel market.

Countries We Export To

UNITED STATES, EUROPE, UK, UAE, SAUDI ARABIA, OMAN, KUWAIT, JORDAN, QATAR, INDONESIA, MALAYSIA, BRAZIL, SPAIN, ITALY, FRANCE, GERMANY, BAHRAIN, SRI LANKA, AZERBAIJAN, AUSTRALIA, AUSTRIA, PHILIPPINES, TURKEY, RUSSIA, IRAN, IRAQ, CANADA, KOREA, JAPAN, YEMEN, FINLAND, ZIMBABWE, HUNGARY, PORTUGAL, VIETNAM, MOROCCO, THAILAND, SOUTH AFRICA, MEXICO, SINGAPORE, GREECE, KUWAIT, POLAND, NEW ZEALAND, SWEDEN, SWITZERLAND, BELGIUM, BHUTAN, BANGLADESH, TAIWAN, ROMANIA, CAMBODIA, KAZAKHSTAN, AFGHANISTAN.