Hastelloy: The Ultimate Solution for Extreme Environments

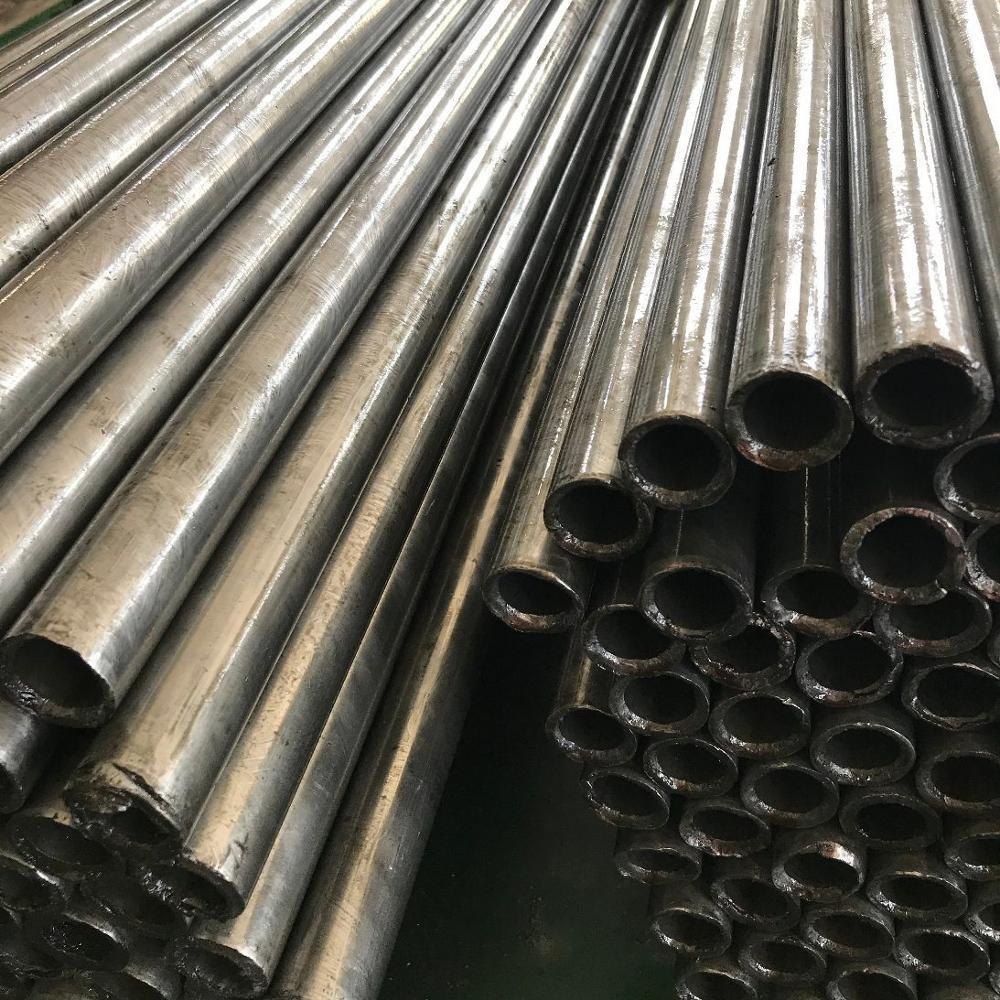

Hastealloy Tubes

Hastealloy Plates

Hastealloy Sheets

Hastealloy Fittings

Hastealloy Flanges

Hastealloy Fasteners

Hastealloy Coils

Hastealloy Bars and Rods

Hastealloy Wires

Hastealloy Coiled Tubes

Schedule Size Chart for Hastelloy

| Pipe Size (NPS) | Schedule 5S | Schedule 10S | Schedule 40S | Schedule 80S | Schedule 160S |

|---|---|---|---|---|---|

| 1/2″ | 0.065″ | 0.083″ | 0.109″ | 0.147″ | 0.294″ |

| 3/4″ | 0.065″ | 0.083″ | 0.113″ | 0.154″ | 0.308″ |

| 1″ | 0.065″ | 0.109″ | 0.133″ | 0.179″ | 0.358″ |

| 1-1/2″ | 0.065″ | 0.109″ | 0.145″ | 0.200″ | 0.400″ |

| 2″ | 0.065″ | 0.109″ | 0.154″ | 0.218″ | 0.436″ |

| 3″ | 0.065″ | 0.120″ | 0.216″ | 0.300″ | 0.600″ |

| 4″ | 0.083″ | 0.120″ | 0.237″ | 0.337″ | 0.674″ |

| 6″ | 0.109″ | 0.134″ | 0.280″ | 0.432″ | 0.864″ |

| 8″ | 0.109″ | 0.148″ | 0.322″ | 0.500″ | 0.906″ |

| 10″ | 0.134″ | 0.165″ | 0.365″ | 0.500″ | 1.000″ |

| 12″ | 0.156″ | 0.180″ | 0.406″ | 0.500″ | 1.000″ |

Mechanical Properties Chart for Hastelloy

| Property | Value |

|---|---|

| Tensile Strength | 690-830 MPa |

| Yield Strength | 240-355 MPa |

| Elongation at Break | 40-60% |

| Hardness (Rockwell B) | 85-95 |

| Melting Point | 1320-1360°C |

| Density | 8.64 g/cm³ |

Specifications Chart for Hastelloy

| Specification | Description |

|---|---|

| ASTM Standards | ASTM B575, B619, B622, B626 |

| UNS Number | UNS N10276 |

| Standard Forms | Sheet, plate, bar, pipe, fittings |

| Heat Treatment | Solution annealed |

| Available Sizes | Customizable to client specifications |

| Certifications | ISO 9001, ASME Section VIII |

Chemical Composition Chart for Hastelloy

| Element | Percentage Composition |

|---|---|

| Nickel (Ni) | 58-71% |

| Molybdenum (Mo) | 15-17% |

| Chromium (Cr) | 14.5-16.5% |

| Iron (Fe) | 4-7% |

| Tungsten (W) | 3-4.5% |

| Cobalt (Co) | 2.5% max |

| Manganese (Mn) | 1% max |

| Carbon (C) | 0.01% max |

| Silicon (Si) | 0.08% max |

| Phosphorus (P) | 0.025% max |

| Sulfur (S) | 0.01% max |

Application Chart for Hastelloy

| Industry | Applications |

|---|---|

| Chemical Processing | Heat exchangers, reaction vessels, evaporators |

| Aerospace | Jet engines, exhaust ducts, gas turbine components |

| Marine | Offshore platforms, subsea piping systems |

| Power Generation | Nuclear reactors, power plant equipment |

| Pharmaceuticals | Drug manufacturing equipment, sterilization units |

| Petrochemical | Refinery components, catalytic crackers |

| Pollution Control | Flue gas desulfurization systems, scrubbers |