High-Quality Alloy Seamless Steel Pipes Suppliers – Amardeep Steel Centre

Welcome to Amardeep Steel Centre, a leading producer and supplier of seamless alloy steel pipes . We provide a broad range of products designed to satisfy the exacting requirements of different industries, all while maintaining an invincible dedication to quality and innovation. Alloy grades such as ASTM A335 Gr. P5, P9, P11, P12, P21, P22, P91, ASTM A213 – T5, T9, T11, T12, T22, T91, and ASTM A691 are featured in our product line. Additionally, we supply pipes in the following schedules: SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, and XXS.

Alloy steel Seamless Pipes Exporters & Stockists In India

Seamless alloy steel pipes are composed of steel combined with other elements including molybdenum, nickel, and chromium. The pipe is extruded during the seamless production process, producing a product with no welded connections that increases strength and longevity. Oil and gas, power generation, petrochemicals, and other industries depend heavily on seamless alloy pipes. The world market for these premium pipes is served by a sizeable number of exporters and stockists in India. This article explores the salient features, advantages, and leading Indian exporters and stockists of alloy steel pipes.

Major Grades and Specification for Seamless Alloy Steel Pipes

ASTM A335 Alloy Seamless Steel Pipes

ASTM A335, also known as ASME SA335, is a seamless ferritic alloy-steel pipe specifically designed for high-temperature service. The various grades offer a combination of high strength, resistance to scaling, and ability to handle high pressures, making them suitable for:

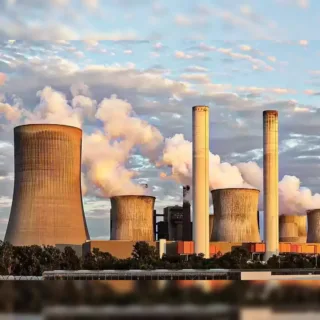

- Power Plants: Ideal for boiler systems, superheater elements, and steam lines due to their high-temperature strength.

- Petrochemical Industry: Used in refineries and chemical plants where high pressure and temperature resistance are critical.

- Oil and Gas: Suitable for use in high-pressure environments such as in oil drilling and gas processing.

ASTM A335 Grades

- Gr. P5: Offers excellent resistance to oxidation and scaling at high temperatures. Used in petroleum refineries.

- Gr. P9: Known for its high chromium content, providing superior oxidation and corrosion resistance.

- Gr. P11: Combines good high-temperature strength with corrosion resistance, widely used in power plants.

- Gr. P12: Similar to P11 but with different chemical composition, making it suitable for specific high-temperature applications.

- Gr. P21 & P22: Commonly used in the power industry for components that must withstand high temperature and pressure.

- Gr. P91: Offers exceptional high-temperature strength and creep resistance, widely used in advanced power plants and refineries.

ASTM A213 Alloy Steel Seamless

Tubes

ASTM A213 (ASME SA213) specification covers seamless ferritic and austenitic alloy steel boiler, superheater, and heat-exchanger tubes. These tubes are designed for high-temperature services and exhibit excellent heat and corrosion resistance.

ASTM A213 Grades

- T5: Suitable for high-temperature services with good heat and corrosion resistance.

- T9: Offers excellent high-temperature oxidation resistance and is often used in superheaters.

- T11: Known for its strength and resistance to heat and corrosion, commonly used in boiler applications.

- T12: Similar to T11 but with different chemical composition, suitable for heat exchangers and boiler components.

- T22: Offers high strength and resistance to scaling at elevated temperatures, used in pressure vessels and heat exchangers.

- T91: Known for its superior high-temperature strength and creep resistance, making it ideal for power plants and high-pressure applications.

ASTM A691 Alloy Seamless Steel Pipes

ASTM A691 specification covers carbon and alloy steel pipes that are electric-fusion welded with added filler metal. These pipes are intended for high-pressure service at moderate temperatures.

Application Industries & Advantages Of Using Alloy Seamless Pipes For Your Projects

Our alloy seamless steel pipes are widely used across various industries due to their durability, high strength, and resistance to corrosion and high temperatures. Key industries include:

- Power Generation: Boiler tubes, superheaters, and heat exchangers.

- Oil and Gas: High-pressure and high-temperature applications, including drilling and processing.

- Petrochemical: Refining and chemical processing equipment.

- Construction: Structural components that require high strength and corrosion resistance.

- Automotive: Exhaust systems and high-performance components.

- Aerospace: High-temperature and high-pressure components.

Specifications Standards of Alloy Steel Seamless Pipe

| Specifications | ASTM A 335 ASME SA 335 |

| Dimensions | ASTM, ASME and API |

| Size | 1/8″NB TO 30″NB IN |

| Tubing Size | 1 / 2” OD up to 5” OD, customs diameters also available |

| Outer Diameter | 6-2500mm; WT:1-200mm |

| Schedule | SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS |

| Grade | ASTM A335 Gr. P5, P9, P11, P12, P21, P22 & P91, ASTM A213 – T5, T9, T11, T12, T22, T91, ASTM A691 |

| Length | Within 13500mm |

| Type | Seamless / Fabricated |

| Form | Round, Hydraulic Etc |

| Length | Single Random, Double Random & Cut Length. |

| End | Plain End, Beveled End, Treaded |

Alloy Steel ERW Pipes Chemical Properties

| Alloy Steel | C | Cr | Mn | Mo | P | S | Si |

| 0.05 – 0.15 | 1.00 – 1.50 | 0.30 – 0.60 | 0.44 – 0.65 | 0.025 max | 0.025 max | 0.50 – 1.00 |

Mechanical Characteristics Alloy Steel Chrome moly Pipes

| Tensile Strength, MPa | Yield Strength, MPa | Elongation, % |

| 415 min | 205 min | 30 min |

Outside Diameter & Tolerance of ASME SA335 Alloy Pipe

EN 10216-2 Seamless Ferritic Alloy Steel Pipes for High Temperature applications

| ASTM A450 | Hot rolled | Outside Diameter, mm | Tolerance, mm |

| OD≤101.6 | +0.4/-0.8 | ||

| 101.6<OD≤190.5 | +0.4/-1.2 | ||

| 190.5<OD≤228.6 | +0.4/-1.6 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, mm | |

| OD<25.4 | ±0.10 | ||

| 25.4≤OD≤38.1 | ±0.15 | ||

| 38.1<OD<50.8 | ±0.20 | ||

| 50.8≤OD<63.5 | ±0.25 | ||

| 63.5≤OD<76.2 | ±0.30 | ||

| 76.2≤OD≤101.6 | ±0.38 | ||

| 101.6<OD≤190.5 | +0.38/-0.64 | ||

| 190.5<OD≤228.6 | +0.38/-1.14 | ||

| ASTM A530 & ASTM A335 | NPS | Outside Diameter, inch | Tolerance, mm |

| 1/8≤OD≤1-1/2 | ±0.40 | ||

| 1-1/2<OD≤4 | ±0.79 | ||

| 4<OD≤8 | +1.59/-0.79 | ||

| 8<OD≤12 | +2.38/-0.79 | ||

| OD>12 | ±1% |

ASME SA335 Alloy Steel Custom Pipes Wall thickness

| STM A450 | Hot rolled | Outside Diameter, mm | Tolerance, % |

| OD≤101.6, WT≤2.4 | +40/-0 | ||

| OD≤101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD≤101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD≤101.6, WT>4.6 | +28/-0 | ||

| OD>101.6, 2.4<WT≤3.8 | +35/-0 | ||

| OD>101.6, 3.8<WT≤4.6 | +33/-0 | ||

| OD>101.6, WT>4.6 | +28/-0 | ||

| Cold Drawn | Outside Diameter, mm | Tolerance, % | |

| OD≤38.1 | +20/-0 | ||

| OD>38.1 | +22/-0 | ||

| ASTM A530 | NPS | Outside Diameter, inch | Tolerance, % |

| 1/8≤OD≤2-1/2 | +20.0/-12.5 | ||

| 3≤OD≤18, WT/OD≤5% | +22.5/-12.5 | ||

| 3≤OD≤18, WT/OD>5% | +15.0/-12.5 | ||

| OD≥20, WT/OD≤5% | +22.5/-12.5 | ||

| OD≥20, WT/OD>5% | +15.0/-12.5 |

Alloy Steel Grade Pipes Heat Treatment

| P5, P9, P11, and P22 | |||

| Grade | Heat Treatment Type | Normalizing Temperature Range F [C] | Subcritical Annealing or Tempering Temperature Range F [C] |

| P5 (b,c) | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| Subcritical Anneal (P5c only) | ***** | 1325 – 1375 [715 – 745] | |

| P9 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P11 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1200 [650] | |

| P22 | Full or Isothermal Anneal | ||

| Normalize and Temper | ***** | 1250 [675] | |

| P91 | Normalize and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

| Quench and Temper | 1900-1975 [1040 – 1080] | 1350-1470 [730 – 800] |

Customization and Innovation

We recognize that every industry has unique requirements, and we offer customization options to meet specific needs. Our team of experts collaborates closely with clients to provide tailored solutions, ensuring maximum efficiency and performance.

Environmental Responsibility

Amardeep Steel Centre is dedicated to environmentally friendly methods. By using recyclable materials and efficient manufacturing techniques, we aim to reduce our environmental impact. Our mission is to produce high-quality goods and make a beneficial impact on the environment.

Global Reach

Amardeep Steel Centre boasts a robust global presence, committed to delivering unparalleled service and quality to clients around the world. Our dedication to prompt delivery and exceptional customer care sets us apart in the industry. Major corporations across the USA, Europe, Asia, and other regions place their trust in our high-quality alloy seamless steel pipes. This widespread trust underscores our reputation for reliability and excellence. By consistently meeting and exceeding the expectations of our international clientele, we continue to solidify our position as a leader in the global steel market.

Countries We Export To

UNITED STATES, EUROPE, UK, UAE, SAUDI ARABIA, OMAN, KUWAIT, JORDAN, QATAR, INDONESIA, MALAYSIA, BRAZIL, SPAIN, ITALY, FRANCE, GERMANY, BAHRAIN, SRI LANKA, AZERBAIJAN, AUSTRALIA, AUSTRIA, PHILIPPINES, TURKEY, RUSSIA, IRAN, IRAQ, CANADA, KOREA, JAPAN, YEMEN, FINLAND, ZIMBABWE, HUNGARY, PORTUGAL, VIETNAM, MOROCCO, THAILAND, SOUTH AFRICA, MEXICO, SINGAPORE, GREECE, KUWAIT, POLAND, NEW ZEALAND, SWEDEN, SWITZERLAND, BELGIUM, BHUTAN, BANGLADESH, TAIWAN, ROMANIA, CAMBODIA, KAZAKHSTAN, AFGHANISTAN.